REAL DATA, REAL VALUE, REAL SAVINGS

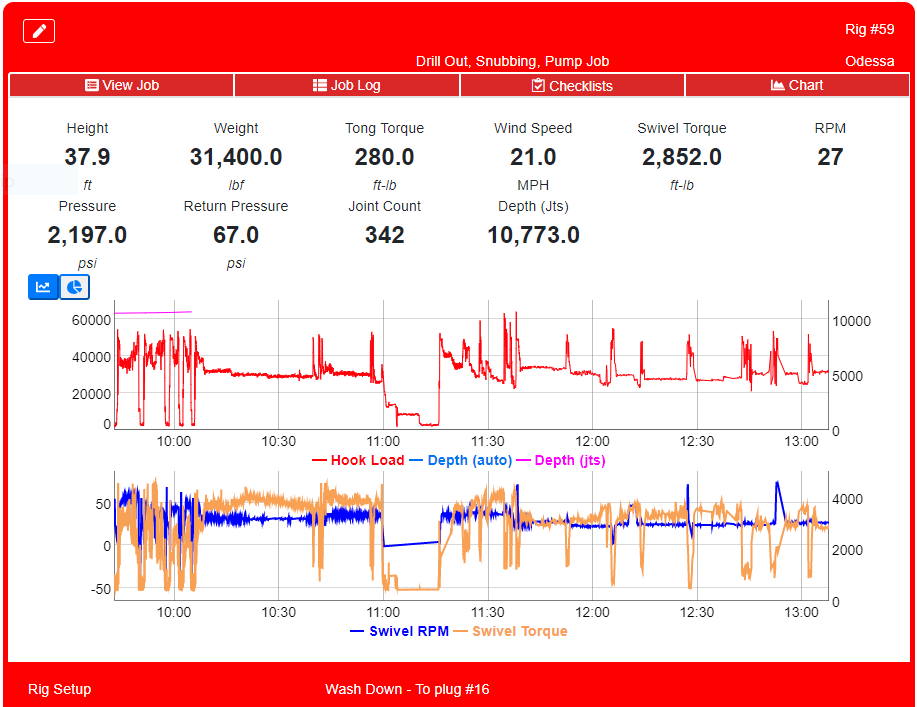

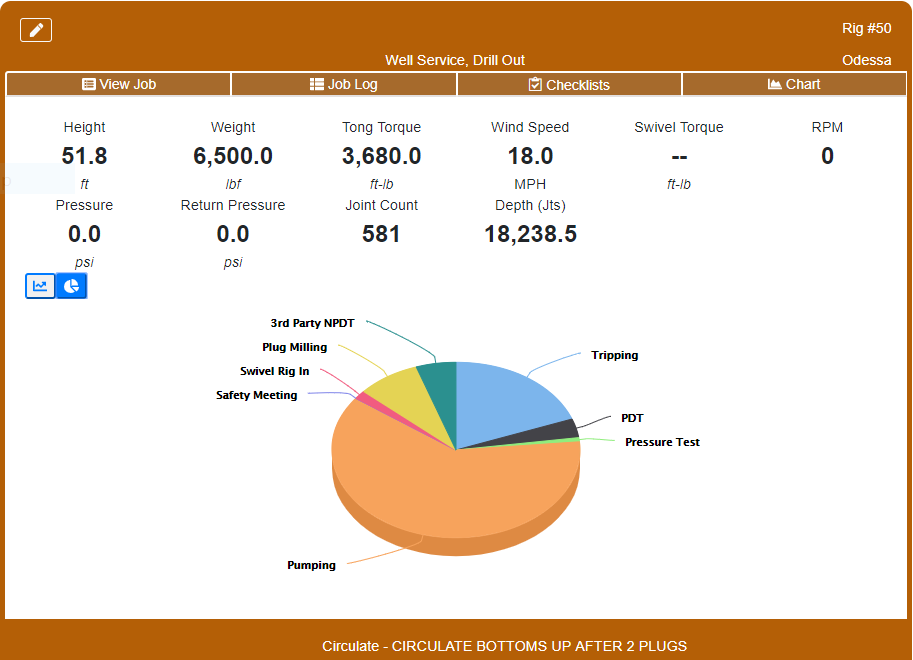

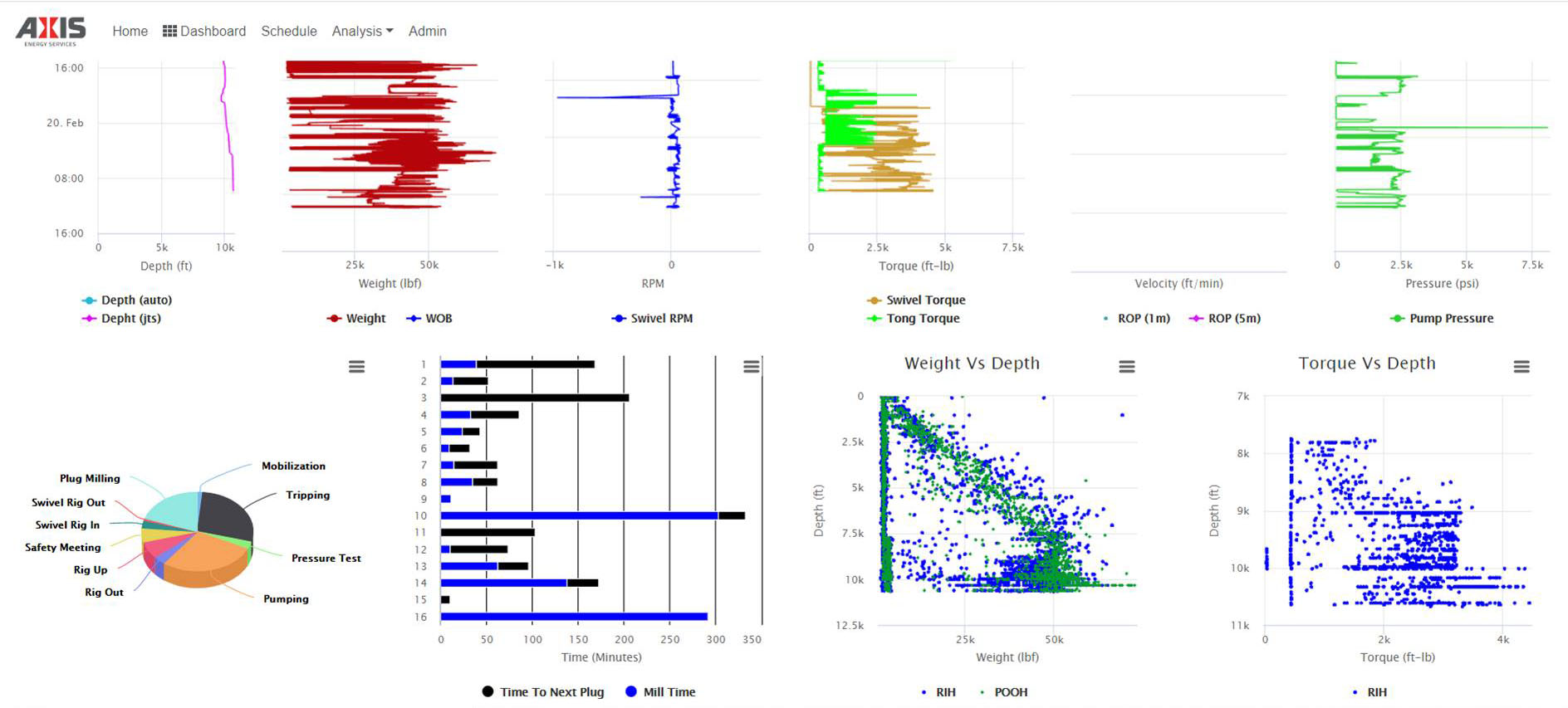

Axis Energy Services introduces a comprehensive digital platform, Axis CORE®, to monitor in real time all of the critical measurements operators need to ensure workovers, cleanouts, fishing jobs, and stick pipe drill outs are accomplished safely and efficiently.

“The idea of collecting critical digital data began with the development of an internal process of continuous improvement for our crews and operations that would be digital, accurate, and in real time,” says Dirk Lee, President and CEO of Axis. “We wanted a real-time view of what was happening at the rig during these critical operations so we could identify problem areas and opportunities to allow us to coach our crews at the earliest possible moment. We also believed the information that would be useful internally would also be valuable to our customers, so we designed the digital platform to allow for broad, real-time customer access.”

Real Data through Rig Monitoring Technology

Axis CORE technology utilizes wireless sensors embedded on critical parts of the rig and support equipment, requiring no additional rig up or delay in moving locations. The sensors provide high-resolution data sampling rates which are displayed in real time to the rig operator and customers on phones, pads, or computers. Some, but not all, of the data collected includes:

- Block height and speed—this safety feature protects the blocks from dropping in order to protect employees and the rig floor and crown

- BOP ram status—this safety feature ensures the rig cannot attempt to pull pipe into a closed BOP

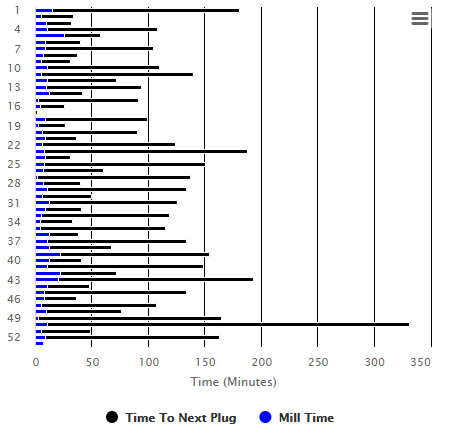

- Average time to drill out a plug—a measure of crew productivity and the brand of frac plug in order to make continuous improvements and set expected times

- Average time to next plug—time is usually dictated by the amount of sand/debris in the well

- Frac plug vendor—Axis collects drill out times on all frac plug vendors, which is useful to customers when selecting a vendor

- Depth in the well

- Weight on bit

- Rate of penetration

- Pump pressure

- Flow back sensor—this data informs employees of the flow that is coming back from the wellbore, as well as how much sand and plug parts are coming back

- Swivel torque

- Swivel RPM

- Tong torque

- Real-time “job log” with notes on events and issues entered by the rig crew that provide a continuous narrative about what is happening at the rig site

- Rig mobilization time

- Real-time KPI reports and detailed post-job analysis reporting

- Third-party downtime

- All company downtime

- Local weather data including wind speed and ambient temperature

All data ecosystem is stored in secure cloud-based storage and can be provided to the customer for their own analysis and post-job processing.

Real Value to Reduce Cost and Downtime at the Well

The CORE data system not only provides a real-time view of all activities at the rig, but also produces a rich set of data so that operations can be executed faster, reducing costs and helping to eliminate downtime.

- Monitoring tongs, swivels, and all moving equipment on the rigs allows us to track how well Axis crews are interfacing with each piece of equipment. Training needs have been tailored to focus on areas where crews are outside of the measured norms, and those who have not met the average connection times are notified in real time when they are outside of the desired “green” zone. Measured best practice is then applied to that rig.

- The system automatically sends a notice to the rig and field management if any desired parameters fall outside of the target. If average plug milling time, which is monitored, falls outside the target for a well, a notice is sent out to explore the underlying causes. Likewise, block weight is monitored to inform management in real time of maximum pull getting close in order to ensure no over-pull beyond the programmed limits.

- As Axis collects more data, the predictive data analytics will allow us to notify customers when we begin to detect equipment issues, downhole motor problems, flow back issues that might lead to incidents, or other unwanted conditions.

Real Savings through Data-Based Decision Making

Axis believes further cost reductions can be achieved by using data-based decision making in determining:

- When to do a pumping sweep of a well during drill out of frac plugs. Often the decision on the optimal time to do a pump sweep today is made based on a rule of thumb or prior experience rather than looking at pump pressure, swivel torque, rate of penetration, and flow back return rates. Reducing the number of pump sweeps during a frac plug drill out could save many hours on a job.

- When to dispense chemicals during a drill out. Again, the decision as to what type of chemicals, how much, and when to release is often based on prior experience and not real-time data. Operators will be able to save money by using less chemicals and reduced pumping times which lowers emissions.

- Whether the use of a rig swivel for plug milling is a better cost-savings approach than using a downhole motor to mill. Axis is working with several customers to evaluate the cost savings of this switch in operations; and so far, the data looks encouraging with only a small increase in milling with the Axis rig swivel versus a motor. Eliminating a motor can save several thousand dollars per day for the operator.

Furthermore, if a customer has multiple rigs working with Axis, a fleet management option is available which allows the customer to schedule rigs and see the real-time progress of all rigs assigned to their jobs.

Axis CORE digital system has been in the field working for more than a year and is a proven, reliable, and highly effective solution to achieve continuous improvement in operations resulting in cost savings for our customers. CORE provides a smart, digital approach to managing well completions, workovers, and production tasks in today’s cost-conscious oil field. Axis will continue to expand the capabilities of CORE as we exploit the many advantages of this system.

Please contact us for a demonstration of this revolutionary digital system and let us show you the Axis difference!

Contact:

Erik Coleman

Vice President of Sales

(432) 999-8716

Erik.Coleman@axisofs.com

Share This Article